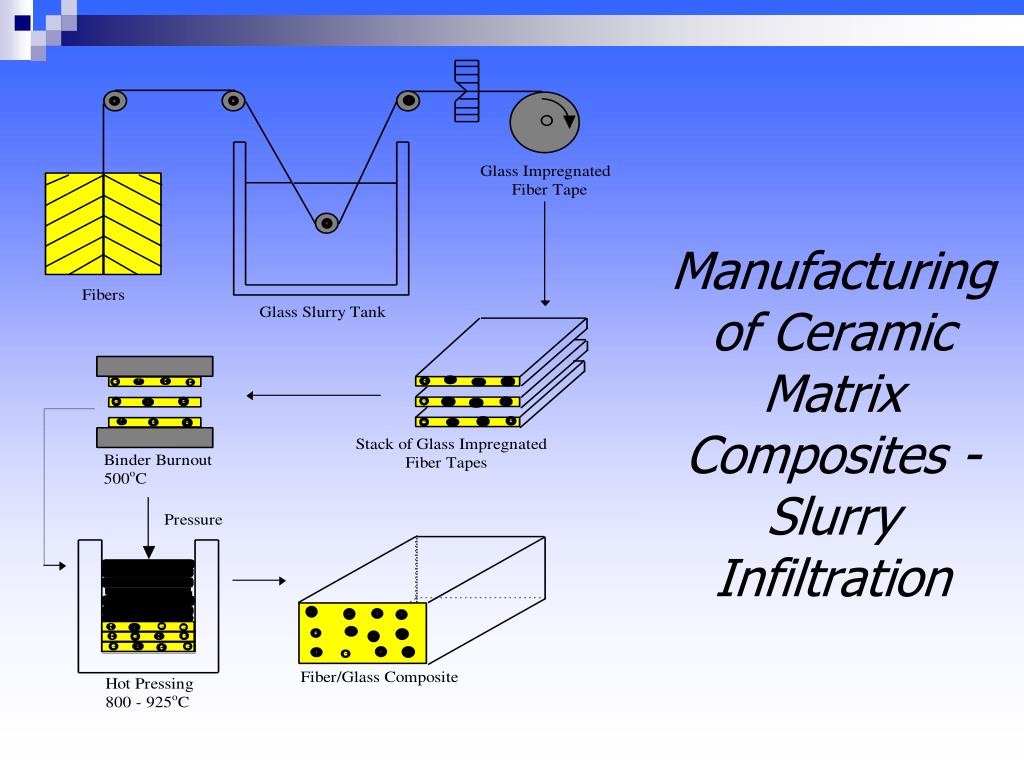

Silicon carbide matrix composites are fabricated by chemical vapor infiltration or liquid phase infiltration methods of a matrix material into a preform prepared from silicon carbide fibers.

Types of ceramic matrix composites ppt.

Naslain mr pomeroy in reference module in materials science and materials engineering 2016.

Grains of one phase separated by grain boundaries of a second phase fig.

Product description applications form matrix color nominal cure temp max.

Silicon carbide ceramic alumina and alumina silica matrix carbon carbon composite 10.

Ceramic matrix composites cmcs may be processed via conventional layup and curing techniques while only requiring a free standing high temperature sinter cycle to prepare them for high temperature use.

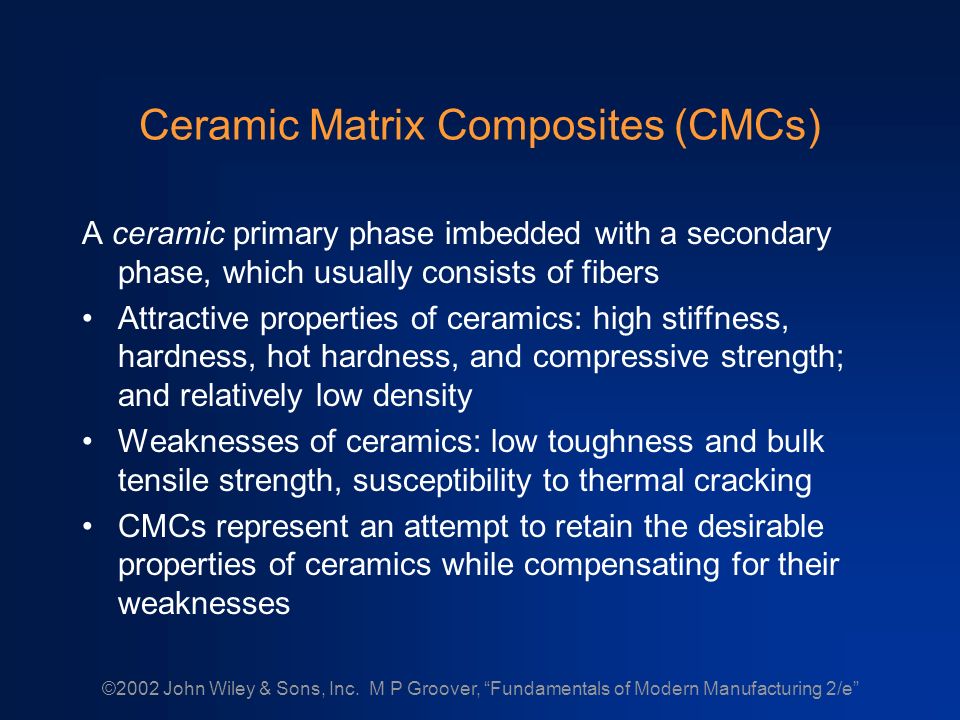

Ceramic matrix composites cmcs are a subgroup of composite materials as well as a subgroup of ceramics they consist of ceramic fibers embedded in a ceramic matrix.

Ceramic matrix composites cmcs generally consist of ceramic fibers or whiskers in a ceramic matrix.

Next generation ceramic matrix composites cmcs are being developed for future applications such as turbine blades top left these may use new technologies such as water like polymers that can be processed into 1700 c capable low density ceramics bottom or nanofibers grown onto silicon carbide sic reinforcing fibers for increased toughness top right.

Both the matrix and the fibers can consist of any ceramic material whereby carbon and carbon fibers can also be considered a ceramic material.

Ceramic matrix composites in design is the property of its rightful owner.

Cmcs are designed to overcome the main drawback of monolithic ceramics namely their brittleness.

Certain amount of elongation in cmc improves the tensile and compressive property.

Properties of cmc tensile compressive behaviour no sudden failure in cmc as like in ceramics.

Material having ceramic as a matrix material in composites called as ceramic matrix composite cmc.

Ovid ko and sheinerman 2011 described nanoceramic composites having different types of microstructural features in bulk form.

Large grains of one phase embedded in a nanocrystalline matrix of a second phase fig.

The powerpoint ppt presentation.

Fracture toughness it limits to ceramics but for cmc s fracture.

The microstructure can have equiaxed nanoscale grains of different phases fig.